- Home

- CHLORINE BASED DERIVATIVE

CHLORINE BASED DERIVATIVE

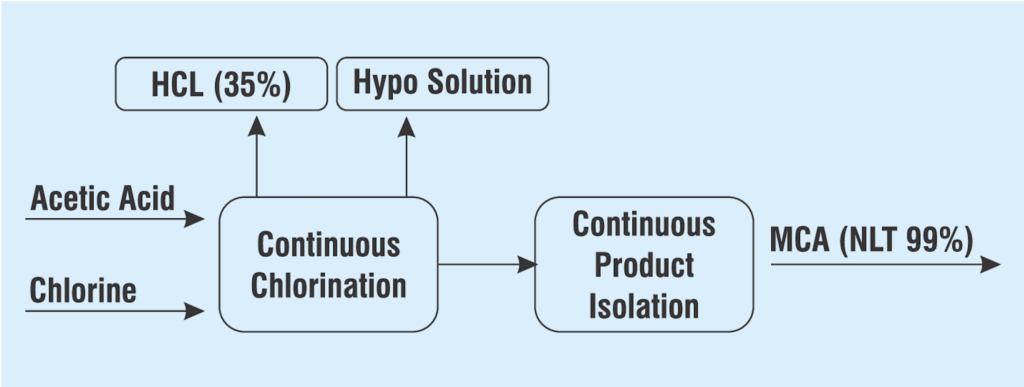

TECHNOLOGY FOR PRODUCTION OF HIGH PURITY MONOCHLORO ACETIC ACID

Chlorine is generated during the course of manufacturing of Caustic Soda. Caustic Chlorine manufacturers are looking for production of value added products from Chlorine. Mono-Chloro Acetic Acid (MCA) is an important chlorine based derivative. Conventionally Mono-Chloro Acid is produced by reaction of Acetic Acid with Chlorine in presence of suitable catalyst such as Sulfur, Sulfuric Acid etc. Post reaction the product i.e. Monochloro Acetic Acid is recovered from reaction mass. The recovered product purity is 99% with some polychlorinated product such as Dichloro Acetic Acid. Most of the conventional processes work in a batch mode.

Geist has developed an innovative process for production of high purity Monochloro Acetic Acid. The new process is able to give product having more than 99 % purity with very low Dichloro Acetic Acid. The new process works in continuous mode thus providing consistent performance with better process safety.

- Produces high purity product (More than 99% MCA with low DCA content)

- Operates in continuous mode thus providing consistence performance

- Better process safety

- Easy to operate and small foot print

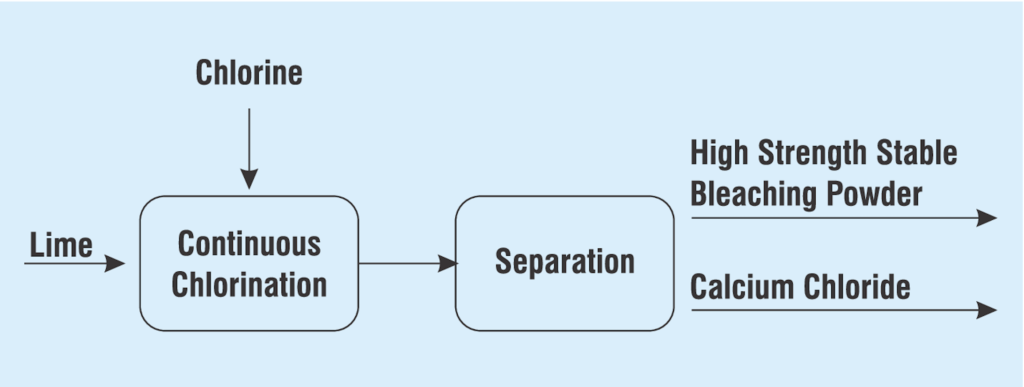

TECHNOLOGY FOR PRODUCTION OF HIGH STRENGTH STABLE BLEACHING POWDER

Chlorine is generated during the course of manufacturing of Caustic Soda. Caustic Chlorine manufacturers are looking for production of value added products from Chlorine. Many manufacturers are installing process plant for production of Stable Bleaching powder. Conventionally Stable Bleaching Powder (SP) is manufactured by chlorination of hydrated Calcium Hydroxide. As per conventional process, hydrated lime is reacted with Chlorine, the resultant product is dried and pulverized to get SBP. The conventional process is able to produce SBP having 32 to 35 percent of available chlorine. Most of the conventional installations are working in batch mode. Because of batch mode operation these installations are very labor intensive.

Geist has developed an innovative process for production of High Strength Stable Bleaching Powder (H-SBP). The new process is able to give product having more than 40 % available chlorine. The process also recovers the by-product i.e. Calcium Chloride in pure form thus generating additional revenue. Geist’s H-SBP process works in a continuous mode thus making it less manpower intensive.

- Produces premium grade product (More than 40% available chlorine)

- Recovers by-product as Saleable product (Calcium Chloride)

- Operates in continuous mode

- Easy to operate and small foot print