WOOW TECHNOLOGIES

TECHNOLOGY FOR PRODUCTION OF ANHYDROUS SODIUM SULFATE

BACKGROUND

Sodium Sulfate is introduced in the caustic chlorine manufacturing process through Sodium Chloride. Being an impurity, Sodium Sulfate needs to be removed from the process. This is achieved using Barium Chloride or Barium Carbonate. The Barium Sulfate generated during the precipitation process is filtered out as wet sludge, along with Calcium and Magnesium impurities. This mixed sludge, having no commercial value, is then disposed of in landfills. Thus, valuable Barium Chloride or Barium Carbonate is consumed merely to generate a waste sludge.

GEIST’S SOLUTION

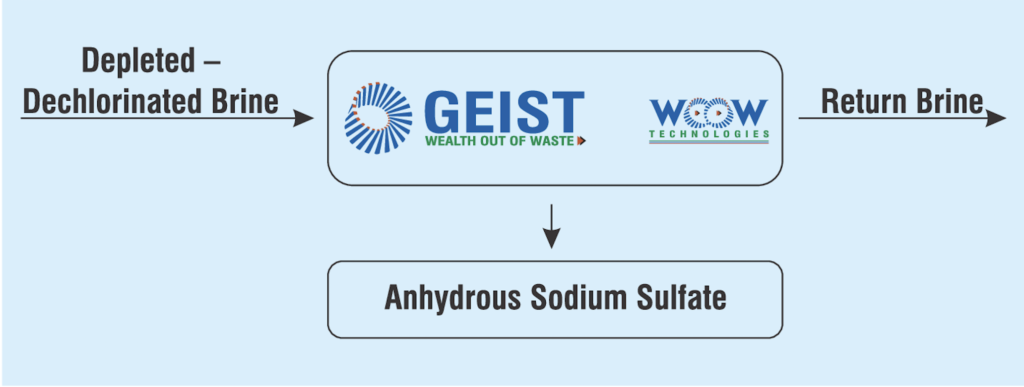

Geist’s WOOW Technology enables the selective recovery of Sodium Sulfate from depleted and de-chlorinated brine. The WOOW Anhydrous Sodium Sulfate Recovery System is a standalone unit that purifies the brine and recovers high-purity Anhydrous Sodium Sulfate. Operating in a continuous mode and without the need for additional chemicals, the system ensures efficient recovery. The purified brine is then returned to the saturator for reuse.

PROCESS OUTLINE

ADVANTAGES OF GEIST’S RECOVERY SYSTEM

- Generate value by mean of recovery of Anhydrous Sodium Sulfate

- Elimination of consumption of Barium Chloride/Barium Carbonate

- Eliminate the generation of Barium Sulfate sludge

- Continuous process technology with very small footprint

TECHNOLOGY FOR PRODUCTION OF

VALUE ADDED CALCIUM AND MAGNESIUM BASED PRODUCTS

BACKGROUND

Sodium Chloride, the main raw material for caustic chlorine production, contains impurities such as Calcium and Magnesium. It is dissolved in water to prepare saturated brine. Before sending this brine to electrolytic cells, it is purified by adding Soda Ash and Caustic Soda. These chemicals cause Calcium and Magnesium to precipitate. The resulting precipitate is sent to a large clarifier for sedimentation. The sediment is then filtered to obtain a Calcium and Magnesium-containing sludge, which is disposed of in a landfill. Thus, the conventional process consumes chemicals like Soda Ash and Caustic Soda for brine purification and generates sludge as a by-product.

GEIST’S SOLUTION

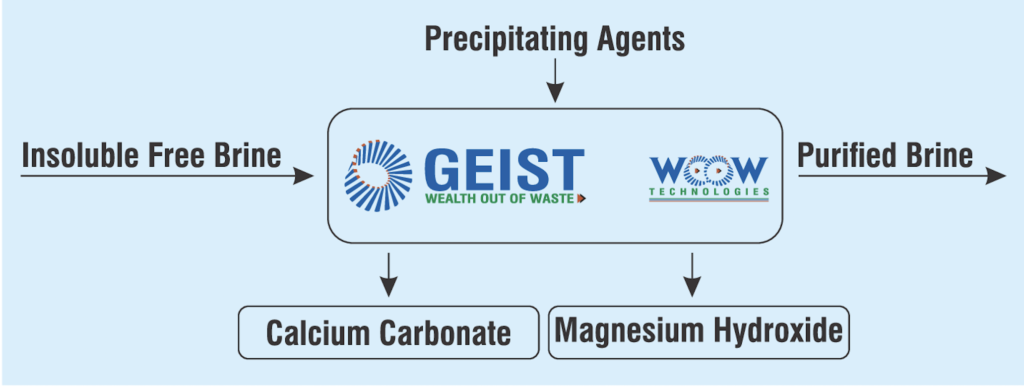

Geist’s WOOW Technology enables the recovery of Calcium and Magnesium from brine in the form of value-added industrial minerals such as Precipitated Calcium Carbonate (PCC), Activated Calcium Carbonate, and Magnesium Hydroxide. These brine-derived products are selectively separated and recovered in high purity, conforming to the required Indian Standards (IS specifications). The system functions in a continuous process with a small footprint, offering a sustainable alternative to conventional sludge disposal methods in brine purification systems.

PROCESS OUTLINE

ADVANTAGES OF GEIST’S RECOVERY SYSTEM

- Generate value by recovery of value added products

- Elimination of Calcium and Magnesium based sludge generation

- Continuous Process Technology with very small footorint