- Home

- Case Studies

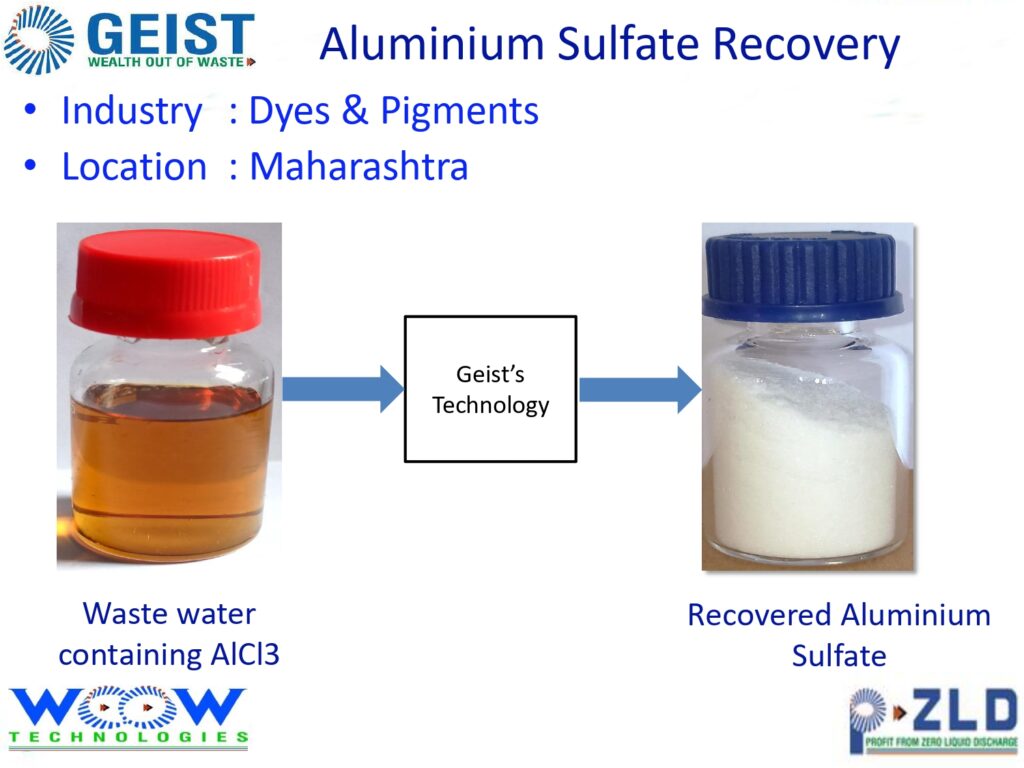

- Dye & Pigment Industry

Dye & Pigment Industry

Dyeing and Pigment Effluent Treatment Solutions

The dye and pigment industry is one of the most water-intensive and polluting sectors. Effluents from dyeing units contain high levels of color, COD, heavy metals, and residual chemicals, making them difficult to treat and harmful to discharge untreated.

Geist specializes in effluent treatment and Zero Liquid Discharge (ZLD) solutions customized for dye and pigment manufacturers across India.

What Makes Dye Wastewater So Complex?

Intense coloration from synthetic dyes

High COD and TDS levels

Non-biodegradable organics

Trace metals and chemicals like chromium, copper, etc.

Such wastewater demands multi-stage treatment systems that go beyond conventional ETPs.

Geist’s Approach to Dye and Pigment Wastewater

We design and implement custom ETP + ZLD systems that:

Handle variable color and load

Achieve >95% color removal

Reduce COD by 80–90%

Recover up to 90% of water for reuse

Our solutions include color-breaking, chemical precipitation, membrane filtration, and high-efficiency evaporation systems — all built for the dyeing environment.

ZLD Systems for Dye & Pigment Plants

Geist’s ZLD setup for dye/pigment industries typically includes:

Equalization and coagulation-flocculation

Color stripping with chemical oxidation

RO + MEE (Multi-Effect Evaporator)

Crystallizer for solid separation

Condensate polishing for water reuse

These help dye and pigment companies stay compliant with pollution control norms and save on fresh water costs.

Chemical Recovery & Sludge Minimization

Geist also offers chemical recovery solutions to:

Reclaim sodium salts, dyes, or acids

Minimize chemical input costs

Reduce volume and weight of hazardous sludge